CATEGORIES

Your Trustworthy Wire Container Supplier

As a professional pet preform container supplier, we can not only supply you one kind of standard products for your goods. Most of the time, we do customized products with Galvanized Foldable Euro Bottle Wire Container or PET Preform Wire Container with Attached Hinged Lid, sizes, materials and types are all can be customized according to your requests, you can trust us all since we do have all of the production machines for roll container and our own painting lines, we will be your good and trustful supplier if you are looking for Mesh Roll Cage Trolley rolling cart Container in the market.You can get more service from us like drawing and material guiding for you, we do have professional technical workers help you do the solution for your transportation.

Why Choose Us

Quality Control

Finding a reputable factory allows you to have better control over the manufacturing process and quality assurance. You can work closely with the factory to ensure that the Cargo rolling mesh cage containers meet your standards.

Quality Assurance

A reputable factory should conduct thorough product testing to ensure that the Collapsible Wire Container with Lid meet industry standards and your specific requirements.

Customization

A good factory should be willing to work with you on customization of Steel Folding Container Shelf, whether it’s adjusting sizes, materials, colors, or other specifications.

Lead Times

The factory should provide realistic and reliable production lead times for your Industrial Wire Mesh Containers. Delays in manufacturing can disrupt your supply chain and affect your business.

what is Wire Container

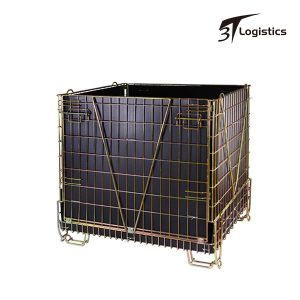

A Galvanized Wire Container with PP, also known as a Rolling Metal Storage Cage or Pet Preform Storage Metal Box, is a type of storage and transport container made primarily from wire mesh or wire grid panels. These Heavy Duty Wire Mesh Container is widely used in various industries for the handling, storage, and transportation of goods. The wire mesh construction provides visibility, breathability, and durability.

Folding Wire Containers come in various sizes and configurations to meet specific industry requirements. The choice of a Galvanized Wire Mesh Container depends on factors such as the type of items being stored or transported, load capacity, and specific application needs.

Benifits of Wire Container

Versatility

Collapsible Wire Mesh Containers are versatile and can be used in a variety of industries, including retail, logistics, manufacturing, and healthcare. They are suitable for transporting a wide range of products, from small items to bulk goods.

Durability

Many Industrial Wire Storage Containers are constructed from durable materials such as steel or reinforced plastic, providing strength and durability. This makes them suitable for heavy-duty use in industrial and commercial settings.

Customization

Wire Mesh Pallet Containers can be customized to meet specific needs. This includes adding or adjusting shelves, incorporating special features, or modifying the dimensions to fit unique requirements.

Security

Some Wire Mesh Industrial Containers come with locking mechanisms or security features to protect the contents during transportation or storage. This can be important in retail settings where merchandise needs to be secured.

Application of Wire Container

Material Handling

Wire Warehouse Wire Container Storage Cages are widely used in material handling applications, such as in warehouses and manufacturing facilities, for the storage and transport of goods.

Retail Storage

In retail settings, wire stainless steel roll container cage trolley Storage Cage is used for the storage of products in the backroom. The visibility of the contents simplifies inventory management and restocking.

Distribution and Logistics

Wire Storage Foldable Metal Wire Mesh Container Box is commonly employed in the distribution and logistics industry for the transport of goods. Their stackable design and durability make them suitable for use in pallet racking systems.

Waste and Recycling

Wire Mesh Container with PP Sheet wire container type is utilized for waste collection and recycling purposes. They provide a durable and visible containment solution for collecting recyclables or managing waste.

Automotive Industry

The automotive industry often uses Foldable Galvanized Wire Mesh Container With Caster for the storage and transport of auto parts and components. The visibility and airflow features are beneficial in this context.

General Storage

Wire Folding Wire Container with Paint Colors are also employed for general storage needs in various environments. Their versatility and durability make them suitable for storing a wide range of items.

Types of Wire Container

Collapsible Wire Pallet Cages

Collapsible Wire Container with Casters have hinged or folding sides, allowing them to collapse when not in use. This feature is beneficial for saving space during storage and transportation.

Stackable wire mesh pallet box

Designed with stacking capabilities, these Stackable Wire Mesh Containers allow for efficient use of vertical storage space. They are commonly used in warehouses and distribution centers where space optimization is crucial.

Half-Drop Gate Wire Mesh Pallet PP Sheet

These Steel Wire Mesh Pallets have a half-drop gate on one side, providing easier access to the contents without fully opening the container. This design is convenient for loading and unloading items.

Full-Drop Gate Wire Roll Container

Full-drop gate Metal Wire Mesh Galvanized Containers have gates that can be fully dropped down, allowing for complete access to the contents. This design is useful for applications where items need to slide in and out easily.

Materials of Wire Container

Steel

Steel is the main material for Collapsible Wire Containers with Casters production, steel, stainless steel, aluminium, copper or any other kinds of steels are all can be the material for this Heavy Duty Wire Mesh Pallet Container with Casters. You can determine the material for your customized Stacking collapsible wire mesh container with Casters.

Coating material

You can do powder coating or galvanized finish on the surface of Stackable Steel Galvanized Metal Wire Mesh Container, it applied for additional protection and aesthetic purposes. These coating treatment provide a durable and even finish that helps resist chipping, scratching, and corrosion.

Additional Components

Wheels with lock is needed and sometimes lid is also needed in using, hinges and the inner tray with a bag, a plastic walls or any other trays can be put inside the Wire Bulk Container Collapsible With Half Drop Door for matching your using especially for PET preform.

what parts of the Wire Container have

- Frame: The frame is the main structural component of the Euro Wire Mesh Container, providing stability and support. It is typically constructed from sturdy wire or tubing and forms the basic shape of the Foldable Storage Cage.

- Mesh Panels: Mesh panels make up the sides, front, and back of the Folding Pallet Cages. These panels are usually made of wire with openings that allow visibility and airflow. The mesh size can vary depending on the type of Collapsible Wire Containers and its intended use.

- Base: The base forms the bottom of the Folding Storage Cage and provides a stable surface for supporting the stored items. The base may have additional reinforcing elements to enhance load-bearing capacity.

- Casters or Wheels: In the case of Folding Wire Mesh Container carts, wheels or casters are attached to the base to enable mobility. The type of wheels used depends on the intended application and the load capacity of the Medium Wire Mesh Container.

How to customized a Wire Container

01

Identify Customization Needs

Clearly define the specific requirements for the customized Large Wire Mesh Container. Consider factors such as size, load capacity, mesh size, mobility features, additional components, and any special features needed.

02

Choose the Base Mobile Wire Security Cages

Select a base metal collapsible mesh containers that closely aligns with your needs. This will serve as the foundation for customization. Choose a Plastic Base Roll pallet that is well-suited for modification and has the necessary structural integrity for your intended application.

03

Size and Dimensions

Determine the required size and dimensions of the Wire Mesh Roll Cage Container. This includes the height, width, depth, and any other critical measurements. Ensure that the customized dimensions meet your specific storage or transportation needs.

04

Mesh Size and Configuration

Specify the mesh size and configuration based on the type of items the Metal Wire Mesh Container with forklift will hold. Smaller mesh sizes provide better containment for smaller items, while larger mesh sizes allow for visibility and airflow.

05

Load Capacity

If your application requires a higher load capacity than standard Foldable Wire Container with Swing Gate offer, work with the manufacturer to reinforce the frame, base, or other critical components to meet the desired load-bearing requirements.

06

Collapsible or Foldable Design

If space efficiency is a priority, consider a collapsible or foldable design. This allows the Collapsible Wire Mesh Container With Wheels to be folded when not in use, saving storage space. Specify the folding mechanism and ensure that it meets your operational needs.

How To Maintain Wire Container

Tighten Fasteners

Periodically check and tighten nuts, bolts, and fasteners. Loose components can compromise the structural integrity of the roll container and affect its performance.

Address Structural Issues

If you notice any structural issues, such as bent frames or weakened supports, address them immediately. Reinforce or repair damaged areas to prevent further deterioration.

Inspect Locking Mechanisms

If your roll container has locking mechanisms, regularly inspect and test them to ensure they are functioning correctly. Repair or replace any faulty locks promptly.

Customization Review

If the roll container has been customized with additional features, shelves, or compartments, periodically review the added components to ensure they are secure and not causing any imbalance.

FAQ

- Q: What is the main feature for PET Preform For Storage Container?

- A: You have to have a inner tray which inside the PET Preform Wire Mesh Container or you can not use it.

- Q: Can you help us with the material and type for my Galvanized Foldable Euro Wire Container?

- A: Yes of cause we can help you choose different parts, types and others parts for it.

- Q: How can you promise the quality for our Steel Wire Mesh Container with Card Holder?

- A: Since we do have more than 25 years production experience and full molds for all of the types for roll container.

- Q: Can you matched wheels for our steel mesh metal container logistics trolley?

- A: You will know the most popular product are Heavy Duty Wire Mesh Pallet Container with Casters in our factory if you know us more.