Description

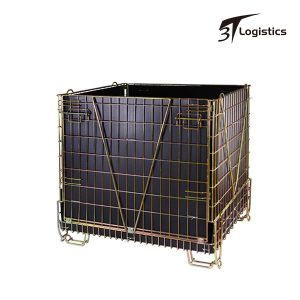

What is galvanized foldable euro wire container

At 3T Logistic Tool, we take pride in our ability to provide exceptional customer service, from the initial inquiry to the final delivery. We work closely with our customers to understand their needs and deliver solutions that meet or exceed their expectations. We offer flexible ordering and delivery options to ensure that your wire containers are delivered on time and within your budget.

We invite you to explore our website to learn more about our products and services and to contact us with any questions or requests you may have. Thank you for considering HT Logistic Tool as your Galvanized Foldable Euro Wire Container factory partner. We look forward to the opportunity to work with you and deliver the best roll container solutions for your business.

Professional experiences

At 3T Logistic Tool, we are committed to providing our customers with competitive pricing without compromising on the quality of our products or services. We understand the importance of delivering value to our customers and are dedicated to finding cost-effective solutions that meet their specific needs for your wire cage on wheels. You can send your requests or printing files to me through email, we will support you the products according your needs.

Super using

Wire container storage cages are a cost-effective solution for transporting and storing goods and They can be reused multiple times and can help to reduce the need for other forms of packaging, such as cardboard boxes or plastic wrap. Beside the durable of the wire mesh cages, the cages can be recycled after using or damaged, we can do a special type of the cage for matching your special using, you can trust us and buy products from us.

Widely used

Overall, our wire bulk containers are a versatile, efficient, and cost-effective solution for transporting and storing goods. Their durable construction and customizable design make them a reliable choice for a variety of industries and applications. All of these elements supply the base of the possibility to make them widely used, bigger size of the product or smaller size of the product are all can use our products, even for a special kinds of metal cages.

The feature of the galvanized surface treatment

Corrosion Resistance

The zinc layer acts as a protective barrier, preventing moisture, oxygen, and other corrosive elements from reaching the underlying steel storage box large. Even if the zinc coating is scratched or damaged, it can still protect the steel through a process called galvanic or cathodic protection, where the zinc corrodes preferentially, protecting the steel beneath.

Durability and Longevity

Galvanized coatings are known for their long-lasting protection. Depending on the environment, galvanized steel lock container can provide decades of corrosion resistance. The lifespan of the coating varies based on factors like the thickness of the zinc layer, environmental conditions, and the presence of pollutants or chemicals.

Maintenance-Free Protection

Once applied, galvanized coatings require little to no maintenance, making them a cost-effective solution over the long term. This is especially valuable in applications where maintenance is challenging, expensive, or dangerous, such as in marine environments or high-rise buildings for steel mesh bins products.

Types of the galvanized method

Hot-Dip Galvanizing

Hot-dip galvanizing involves immersing the metal (usually steel or iron) in molten zinc. The mesh wire container is cleaned first by being dipped in a series of chemical baths to remove oil, dirt, and rust. Then, it’s dipped into a molten zinc bath at a temperature of around 450°C (842°F). When the metal is removed, a zinc coating forms as the zinc reacts with the oxygen and carbon dioxide in the atmosphere. This method provides a thick, durable coating that offers excellent corrosion resistance.

Electro-Galvanizing

In electro-galvanizing, a layer of zinc is deposited onto the steel mesh basket large using an electrical current. The metal is placed in an electrolyte solution containing zinc ions and is then connected to the negative terminal of a power supply, while a zinc electrode is connected to the positive terminal. The electric current causes zinc ions to move towards the metal surface, where they are reduced and form a coating. This method produces a thinner and more uniform coating than hot-dip galvanizing.

Mechanical Plating

Mechanical plating involves coating the steel mesh stackable bins with a mixture of zinc dust, water, and glass beads or other impact media. The mixture is placed in a tumbling barrel, and the impact media physically bond the zinc particles to the metal surface through mechanical energy. This method is often used for small parts and provides a smooth, uniform coating. Compare with the other two different kinds of galvanized, you can choose this mechanical plating for your metal product also.

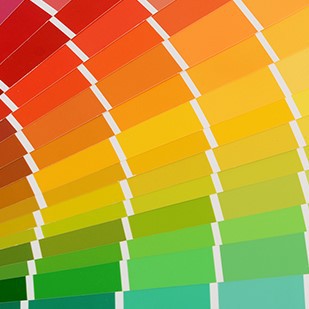

The colors of the galvanized

Popular color silver

The most poplar color of galvanized is silver, most of the warehouse wire container are made with this color, this kind of color can be made for your any metal products including the wire mesh container or solid metal plate.

Other colors

Most of the people thought the galvanized treatment for the surface is only can be chosen with silver, but in fact the colors of wire container with casters can be do any colors for you, black, blue or any other colors are all can be got from us.

What about your service

Custom support

As a professional factory whose can do all parts of the cages, custom method is the base job that we can do for you, so the size, color, surface treatment or the special style of the steel stacking box are all can do for you, you can get a suitable cages which matching your using.

Free parts support

The free parts will be give to you by the different steel metal boxes of the order, no matter for the shipment which we put in the container or after you received the container, for the using if you use the cages for damaged in different situation.

Good warranty

The warranty of the metal cage are good for support you, you can get guild for the cage during production, you also can get support from us for free parts for the beginning 3-4 months of the time when you receiving the container.

How to set up the order from you

- 1. Get free quotation

Get quotation for the steel bin store from us in a quick time will give a big help for you, you can contact with us and send all of the specifications of the cages which you need, we will calculate the price for your metal product and send you the shipping cost for you also, to make you have a clear mind for the price.

- 2. Get sample from us

A sample of custom steel box large can be get from us freely, we can do the sample which according to your request and this sample will be made by hand, so the size or the surface treatment will be not that super like bulk order, but you can test it before the bulk order production, to make sure they are enough for your using.

- 3. Bulk order production

After all of the information and confirmed, the production will be begin for the production, the production time is around 35 days to 50 days which depend on the quantity of the order, we can help you do the rush order if you needed, just let us know the required delivery time is ok and we will try to arrange them for you.