Description

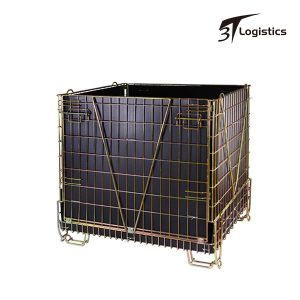

What is heavy duty wire mesh container

Thank you for considering 3T Logistic Tool as your Heavy Duty Wire Mesh Container factory partner. We are committed to sustainability and environmental responsibility in our manufacturing process and are proud to offer eco-friendly roll container solutions. Please don’t hesitate to contact us with any questions or requests you may have.

At 3T Logistic Tool, we strive to maintain competitive pricing while providing high-quality products and exceptional service. We understand that our customers’ success is closely tied to their ability to manage costs and improve efficiency, which is why we are committed to providing cost-effective solutions that offer maximum value.

We believe that every business deserves access to top-quality products that are built to last. That’s why we work closely with our customers to ensure that our wire containers are designed and built to meet their exact specifications. Whether you need a custom color, size, or material, we’ve got you covered.

Smooth surface

The surface of the Euro Wire Container is made with very smooth that allow you can use them for cloth or any other kinds of product which is easy damaged, we support you with different sizes goods of using with our boxes and give you better solutions for them even for powder using.

Reinforced base

The base plate are chosen thicker materials and the sizes of the tubes are bigger, we chosen solid tube for the base plate frame if your want to loading much heavier goods during production, Wire Roll Container can be used for stone or mines which for heavy goods transportation.

Tacking feature

Stacking feature is the necessary element which we have to consider about, allow you can use them for storage or transportation goods with less cost and less space after stack them together with multiple sizes, you can tell us your request and we can help you do the suitable product.

Why Choose us

Support for custom product

We work closely with our customers to understand their unique needs and requirements, and offer customized Heavy Duty Wire Mesh Container solutions that are tailored to their specific material handling needs. Our team of experts can help businesses optimize their material handling processes, reduce waste, and increase efficiency, resulting in significant cost savings over time.

Good price

You can get free quotation from us, we can service you high quality product with best price. Do not hesitate to let us know your idea for your products, so we can know how to send you our suggestions. The price of the Wire Mesh Container With Caster also can be got from us with better, you can get supported from us for the price of the cage.

Super quality

Our commitment to quality extends beyond our products to our customer service. We understand that every customer is unique, which is why we’re dedicated to providing personalized service and support. Our team of experts is always available to answer your questions, offer guidance, and help you find the perfect solution for your business.

Types of heavy duty wire mesh container

Security Wire Mesh Containers

Security Folding Steel Wire Container feature a lockable lid or cover to prevent unauthorized access to the contents. They are used when extra security is needed, such as for storing valuable or sensitive items.

Heavy-Duty Wire Mesh Containers

Heavy-duty Stackable Wire Mesh Containers are built with thicker wire and stronger frames to handle particularly heavy or abrasive materials. They are commonly used in industries like metalworking, construction, and recycling.

Half-Drop Gate Wire Mesh Containers

These Steel Wire Mesh Pallets feature a half-drop gate, which provides easy access to the contents without the need to remove the entire lid or top panel. This design is convenient for accessing items quickly and efficiently.

How we confirm the metal cages

Cost of the sample

The sample of the wire mesh container are supplied freely for you, but you need to bear the cost of the shipment, all cost of the cage including the shipment will be deduct from the order, you can get the sample from us for a quick time.

Delivery of the sample

You can get a quick delivery from us for free sample of Folding Pallet Cages, the sample will be delivery by air instead of sea shipping, so the cost will be more for air shipping of the big size of the metal cages, we will pack them by wooden box.

Confirm the order

You can test the sample of Stackable Wire Container after you got the sample, so you can confirm the sample or change some design of the sample for your bulk order, than we can confirm the bulk order of the metal cages and prepare the production.

How to control the quality of the cage

Loading weight

The loading weight of the Collapsible Wire Containers with Casters can be customized with different, no matter how is the weight loading capacity of the cage, you have to test it before shipment and after finished the assemble of the metal cages.

Surface treatment

The surface of the Galvanized Wire Container need to be done with smooth, we Inspect the surface for any defects such as sharp edges, burrs, or rust. Ensure the finish is smooth and even, so you do not need to worry about anything if you use them for easy damaged products.

Other features

The stackable or the nestable feature of the cages need to be controlled by us, for the heavy loading of the cage or the stackable feature of the cage are all can be got from us, we can give more support for you for special request of your cages.

How to control the quality of your cage

Raw material checking

Check the type and grade of wire used, ensuring it meets the specifications for strength, durability, and corrosion resistance. You have to control the wire diameter and mesh size are consistent and within specified tolerances, the materials of the cages can be chosen with different and you have to checking them carefully.

Parts inspection for metal cage

Each parts of the Wire Mesh Roll Cage Container need to be controlled by our checking factory, each part of the cages need to be controlled and checking with high quality. We checking each part of the cages during assemble them, including hinges, walls, bottom, wheels or any other parts of the cages.

Final Inspection

Conduct a final inspection of the completed Steel Wire Mesh Container to ensure they meet all quality standards and specifications.Maintain detailed records of the inspection process, including any defects found and corrective actions taken. Documentation should include material certificates, test reports, and inspection checklists.